FS-1110 | September 2020, updated April 2024

Septic Systems and Best Available Technologies

Septic systems, or onsite wastewater treatment systems, are well-established and effective tools for treating wastewater for homes, businesses, and small communities. Currently, 20% of U.S. households and more than 420,000 homes in Maryland utilize this type of wastewater treatment.

Historically, a relatively simple gravity system or conventional septic system are the most prevalent types in use today. Advanced treatment, enhanced nutrient removal or best available technology (BAT) systems are relatively new (last 20 years) technologies that, as the terms suggest, provide for improved treatment of wastewater and reduction of nitrogen and other water quality parameters that can negatively impact surface and groundwaters.

Regardless of the type of system you have, following guidelines for routine maintenance can help save you money, protect the value of your property, keep you and your neighbors safe from health threats and protect the environment.

Wastewater is Comprised of Solids, Nutrients such as Nitrogen and Phosphorus, Minerals, Pharmaceuticals, as well as Harmful and Beneficial Bacteria

Septic systems are designed to treat wastewater using a combination of natural chemical, biological, and physical processes in which beneficial bacteria feed on the solids and nutrients. Bacterial decomposition of waste results in fewer nutrients, such as nitrogen, in the wastewater and elimination of pathogens of concern to human health.

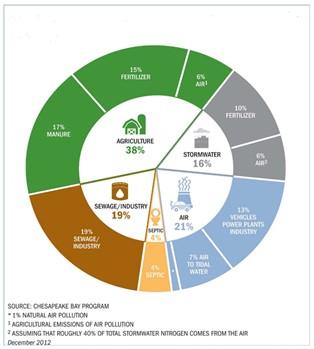

Septic systems are one of five sources of excess nutrients identified in the Chesapeake Bay Total Maximum Daily Load (TMDL). It is estimated that septic systems currently are responsible for 6% of the total load of nitrogen to the Bay across the watershed.

How does a Septic System Work?

The essential components of a septic system are a septic tank, distribution box, drainfield, and the natural soil under the drainfield (Figure 1). The tank is a watertight container constructed of concrete, fiberglass, or plastic. It is designed for temporary storage, settling of wastewater to separate the solids, fats and grease from liquids, and partial treatment of the solids. Conventional tanks have two chambers to aid in solids separation. Some decomposition of solids occurs in the septic tank then goes out to the soil absorption component (such as a drainfield), to receive treatment from the soil.

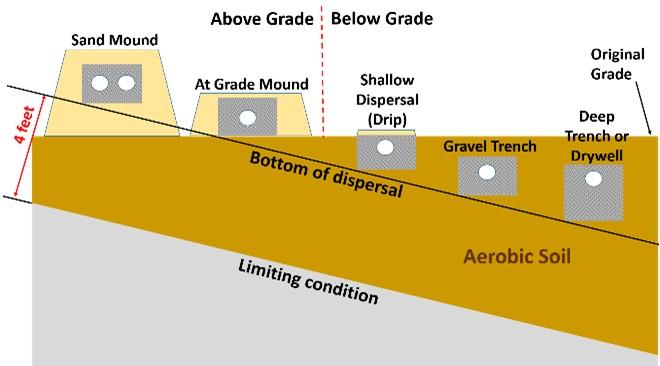

The soil absorption component distributes the liquid effluent over a predetermined area of soil. The septic system design is based on key factors such as number of bedrooms in the house, a comprehensive site evaluation including onsite soil assessment to determine the ability for wastewater to infiltrate into soil layers, and the depth to the water table or another confining layer (Figure 2).

Septic systems are typically designed by a licensed environmental health specialist or professional engineer and must be approved by the local approving authority to ensure the design complies with the state and local regulations.

Over time, a natural film of beneficial bacteria called biomat will form on surfaces within the soil absorption component and help breakdown harmful pathogens. Conventional septic systems typically rely on gravity flow, and include trenches filled with gravel or sand.

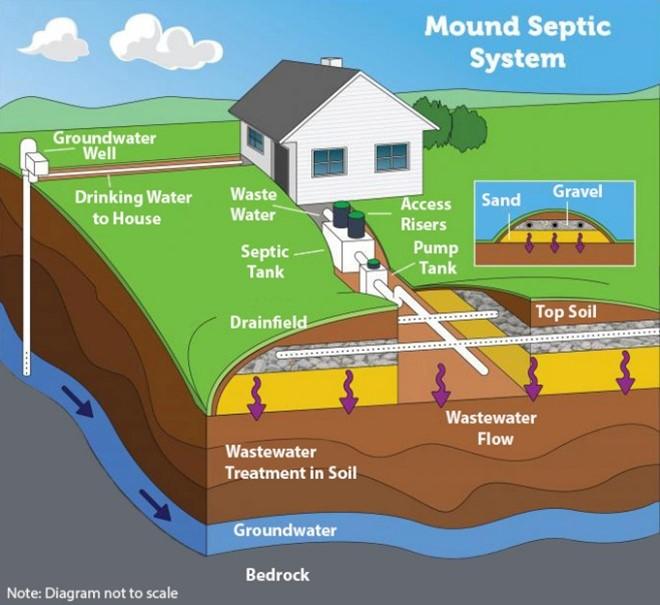

More advanced types of septic systems include at-grade mounds or sand mounds and other pressurized dispersal systems. Pressurized systems may be necessary in sites with more challenging conditions, such as marginal soil types, high water tables and other limiting conditions.

Sand mounds and at-grade mound dispersal systems include a pumping component to pressurize the wastewater distribution network (figure 3).

The soil is integral to waste treatment since this is where the bulk of chemical and biological treatment occurs, and 20-40% of nitrogen reduction. The soil acts as a natural filter to reduce nutrient loads and remove harmful bacteria. In addition to nitrogen removal, studies have shown that some of the personal care products, pharmaceuticals, etc., referred to as “contaminants of emerging concern” can be broken down in the treatment process, especially in the upper layers of soil. This role of soil in waste treatment emphasizes the importance of proper site selection to identify appropriate soil types and adequate vertical distances from the bottom of the drainfield to the limiting layer.

I'm a Homeowner with a Septic System - What Should I Know?

Septic systems can be an efficient and cost-effective way to safely treat and dispose of household waste, but they require the care and diligence of the homeowner.

Homeowners can help prolong the life of the system by following these recommended operation and maintenance practices:

- Solids will accumulate in the septic tank over time. Tank pumping is recommended every three to five years;

- To conserve water, use it efficiently, fix leaks, and use water-saving appliances;

- Do not dispose of chemicals down the drain. Check with your local waste disposal agency for recycling hazardous chemicals;

- Avoid using garbage disposals and do not pour fats, oils and grease down the drain;

- Do not drive vehicles or machinery over the drainage component; mowing is okay;

- Plant grass but not trees or shrubs in the drainfield, since the roots may damage the septic system;

- Do not build, pave or add fill over any area of the septic system;

- Flush only toilet paper – no wipes, feminine hygiene products, etc.;

- Ensure stormwater runs away from tank and drainfield;

- Ensure power to the system if it utilizes a pump, or an advanced treatment unit.

When a septic system is not properly maintained, it potentially could fail. Septic systems can fail when the soil in the drainfield cannot handle the quantity or quality of the wastewater coming out of the septic tank. This can result in wastewater backing up into the house or pooling up to the surface of the drainage component.

Septic systems can also fail if a blockage develops anywhere in the system. The soil absorption component of the system requires unrestricted wastewater flow, so it's best to limit any materials going down the drains that could limit wastewater infiltration. If a homeowner suspects that their septic system is failing, they should contact their local approving authority, which can be found at: https://go.umd.edu/SepticLAA

For more information on how to best care for a septic unit, homeowners may contact the MDE On-site Systems Division, or view the U.S. Environmental Protection Agency (EPA) website: https://www.epa.gov/septic

What are Best Available Technology (BAT) Septic Units?

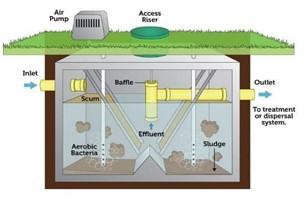

Best Available Technology (BAT) units, also known as advanced or aerobic treatments units (ATU) are septic system components that use technology approved by MDE for removing nitrogen from onsite sewage disposal systems. While conventional septic tanks typically have two chambers to aid in solids separation, BAT units and other advanced treatment systems may contain multiple chambers (Figure 4).

Each of the chambers within a BAT has a specific function including solids settling, nitrification and denitrification, and clarification. Some BAT units recirculate clarified wastewater either to the settling chamber, or to specialized media populated with bacteria to enhance nitrogen removal.

The conditions in a conventional septic tank can generally be described as anaerobic, meaning there is no oxygen present. In contrast, a BAT unit is designed to provide both anaerobic (without oxygen) and aerobic (with oxygen) conditions, to maximize natural processes of nitrification and denitrification. The primary form of nitrogen in wastewater is ammonia, which beneficial bacteria will convert to nitrite. In the presence of oxygen, nitrite can then be converted to nitrate in a process called nitrification. Nitrification must occur for the bacteria to convert nitrate to nitrogen gas in a process called denitrification. When denitrification occurs, this allows the nitrogen to be released into the atmosphere as a gas, instead of entering groundwater as nitrate.

Although BAT units may replace the traditional septic tank component of a septic system, a drainfield or soil dispersal system is still necessary for the dispersal of wastewater effluent, like a conventional system.

BAT Units Have Important Benefits

According to studies, a conventional septic tank reduces nitrogen by approximately 5-10%. Maryland regulations require that a Class I BAT unit reduce nitrogen by a minimum of 50%. For current Class I BAT units in Maryland, the advanced design and aeration features of BATs have been shown to provide nitrogen reduction of 54%-77%, depending upon the specific BAT technology. In addition to the enhanced nitrogen reduction capability, the effluent of a BAT unit is lower in biological oxygen demand and total suspended solids, resulting in a clearer, less turbid liquid compared to conventional septic tank effluent. This improved water quality can prolong the life of a drainfield, which is especially important in small lots where replacement of a drainfield may not be possible.

BATs are an important tool in reducing impacts on ground and surface waters. Since septic systems ultimately allow treated wastewater to enter groundwater, ensuring that systems are properly maintained is critical in reducing risks to drinking water and public health. Average monthly electric costs for Maryland approved BAT units are $3.24 - $18.86 (See Appendix) and are less or comparable to annual utility costs of an electric clothes dryer. Disconnecting power to your unit will negatively affect the system efficiency and quality of effluent, resulting in reducing the lifespan of your drainfield. For that reason, where BATs are installed in Maryland, state regulations require that the property owner must regularly service their BAT and maintain it in accordance with the manufacturer’s recommendations.

Your septic system (with or without a BAT unit) provides an important wastewater management service to you and your property, adding value, and can be thought of as the most expensive home appliance. Consequently, it makes sense to care and maintain it to keep it functioning for many years.

Bay Restoration Funding for BAT Units is Available to Upgrade Septic Systems

The Chesapeake Bay’s water quality and ecosystems have been experiencing decline due to pollutants such as excessive amounts of nutrients, sediment, and other contaminants (see Figure 5 for sources of pollutants). To target excessive nutrients from sewage disposal (from both wastewater treatment plants and on-site sewage disposal systems), the Bay Restoration Fund (BRF) was signed into law on May 26, 2004. This bill created a fund financed by users to upgrade sewage disposal systems with nutrient-reduction technology.

For Maryland residents whose homes are connected to public sewer, the Bay Restoration Funds go to upgrading Maryland’s wastewater treatment plants with enhanced nutrient removal (ENR) technology. For citizens whose homes use on-site sewage disposal systems, the funds are used to upgrade systems with nitrogen-reduction technology using BAT units. Funds can also be used to connect houses to public sewer and to plant cover crops, to reduce nitrogen loading from agriculture.

The annual BRF revenue dedicated to septic upgrades is approximately $15 million. The funds are prioritized to upgrade failing systems, and may also be available for new systems to serve new construction. Funds can cover up to 100% of the BAT unit cost, installation cost, and currently provides two years of operation and maintenance. For low-income residents, additional grant funding of the soil absorption component may also be for households, non-profit entities, and commercial entities, with priority going to failing systems. To learn more about the qualifications and prioritization for funding, please visit the following site: https://mde.maryland.gov/programs/Water/BayRestorationFund/OnsiteDisposalSystems/Pages/index.aspx

Submit Application for BRF Funding to Your County’s Environmental Health Department

Contact information for each county is available here. Or follow this link: https://mde.maryland.gov/programs/water/BayRestorationFund/OnsiteDisposalSystems/Documents/Maryland%20Contact%20Page%2004302014.pdf

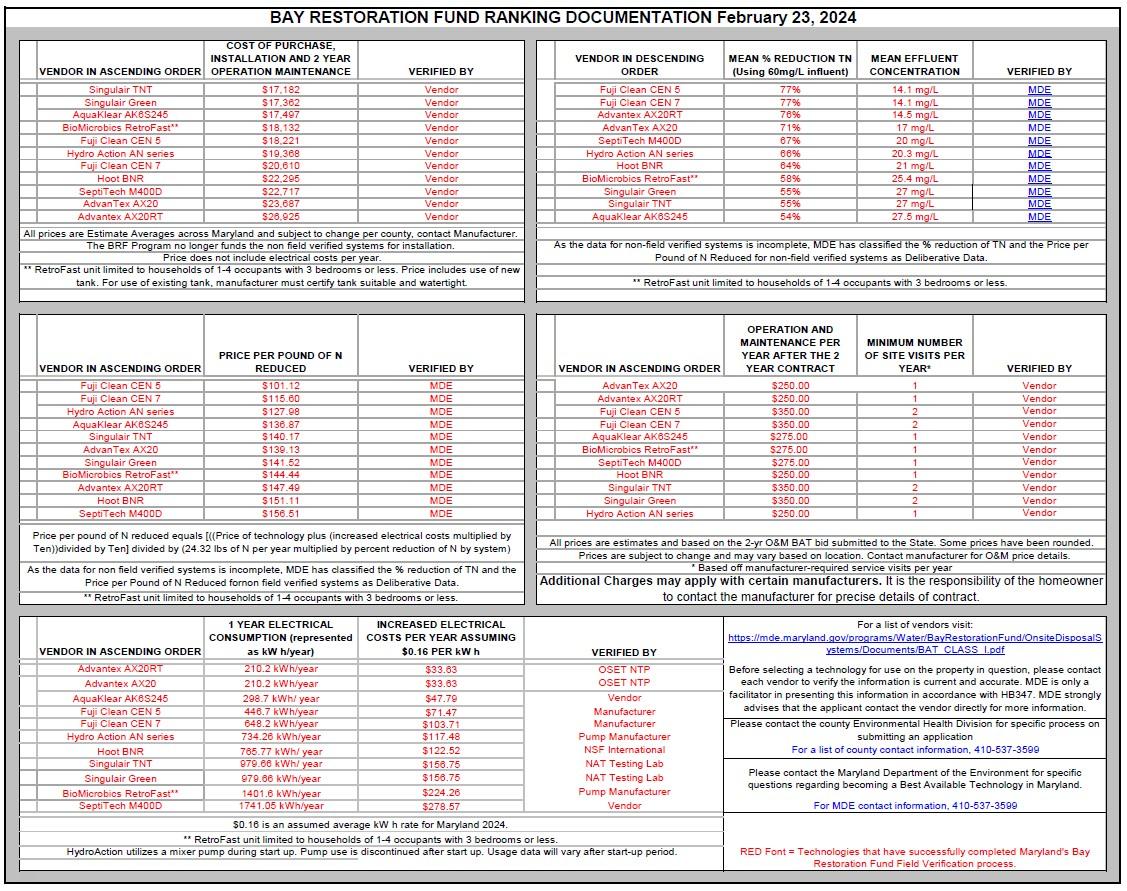

If granted BRF funding, homeowners may choose which pre-approved BAT technology they would like installed. MDE has created a BAT ranking document to assist homeowners with this decision. MDE and the county health department may also provide guidance on which technology type is best suited to the homeowner’s specific needs, based on factors such as house size, water use, and the soil’s ability to treat the wastewater. The MDE BAT Ranking Document is available here. Or follow this link: https://mde.maryland.gov/programs/water/BayRestorationFund/OnsiteDisposalSystems/Documents/BAT%20Ranking%20Document.pdf

Homeowner Will be Responsible for Having a BAT Unit Serviced at Least Annually

The Code of Maryland Regulations (COMAR) 26.04.02.07(E) requires that the property owner of a BAT unit ensures that the BAT system receives operation and maintenance performed at a minimum of once per year by a certified service provider. Certified service providers can be found at the following link: https://mde.maryland.gov/programs/water/BayRestorationFund/OnsiteDisposalSystems/Documents/Service_Provider_Companies.pdf

Homeowners may become certified to perform their own operation and maintenance. This is a two-step process in which the homeowner must complete an MDE-approved BAT Operation and Maintenance course and receive specialized training on their particular BAT technology type. Trained and certified homeowners with a BAT system are responsible for submitting the proper documentation to notify MDE every time they service their unit. While this allows homeowners to perform their annual operation and maintenance, it does not qualify them to perform any repairs of the unit or to pump the unit.

Please contact the MDE Onsite-Systems Division for more information on the certification process, and the limitations of this certification.

Regardless of who services the unit, homeowners should keep detailed records noting when:

- the unit was serviced,

- it was pumped;

- various repairs were needed.

If homeowners follow all these recommendations, they can help ensure the longevity and function of their system.

Appendix

ANDREW LAZUR

University of Maryland Extension

lazur@umd.edu

SARA ALBRECHT

Maryland Department of the Environment

Sara.albrecht@maryland.gov

JENNIFER DINDINGER

University of Maryland Extension

jdinding@umd.edu

This publication, Septic Systems and Best Available Technologies, FS-1110, is a part of a collection produced by the University of Maryland Extension within the College of Agriculture and Natural Resources.

The information presented has met UME peer-review standards, including internal and external technical review. For help accessing this or any UME publication contact: itaccessibility@umd.edu

For more information on this and other topics, visit the University of Maryland Extension website at extension.umd.edu

University programs, activities, and facilities are available to all without regard to race, color, sex, gender identity or expression, sexual orientation, marital status, age, national origin, political affiliation, physical or mental disability, religion, protected veteran status, genetic information, personal appearance, or any other legally protected class.

When citing this publication, please use the suggested format below:

Lazur, A., Albrecht, S., & Dindinger, J. (September 2020, updated April 2024). Septic Systems and Best Available Technologies (FS-1110). University of Maryland Extension. go.umd.edu/FS-1110